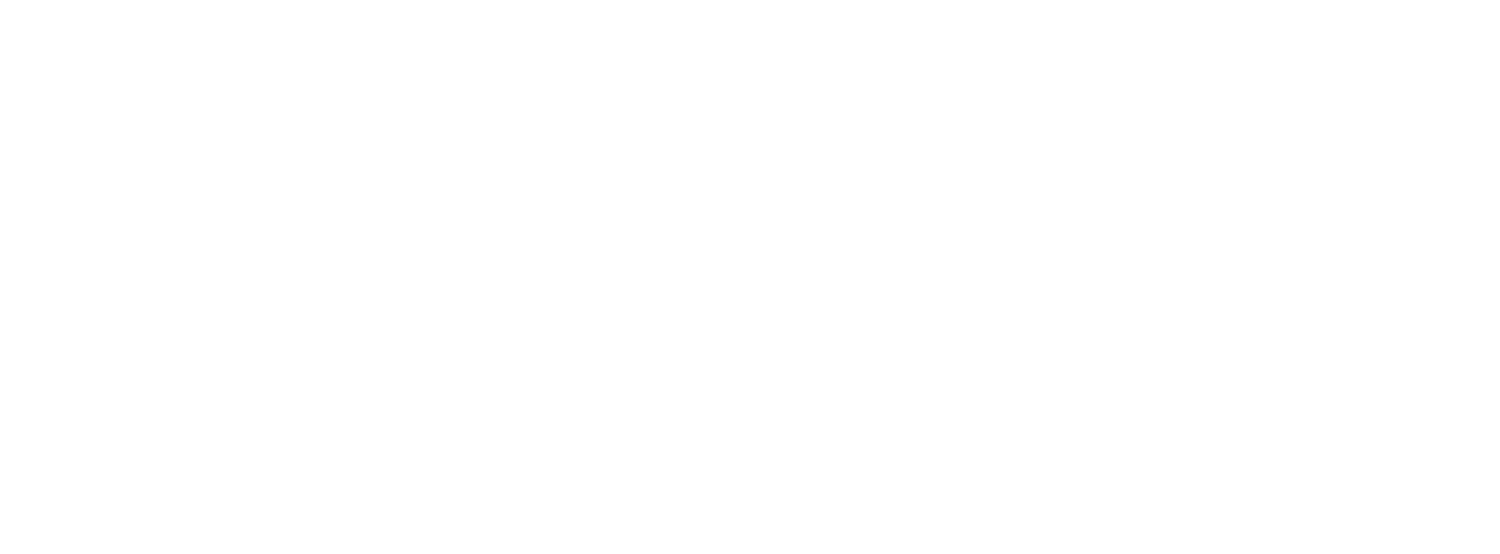

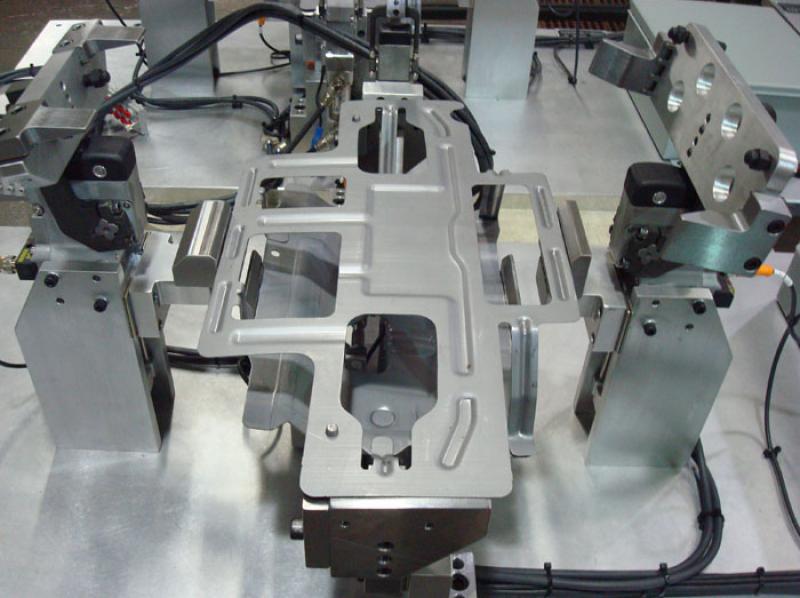

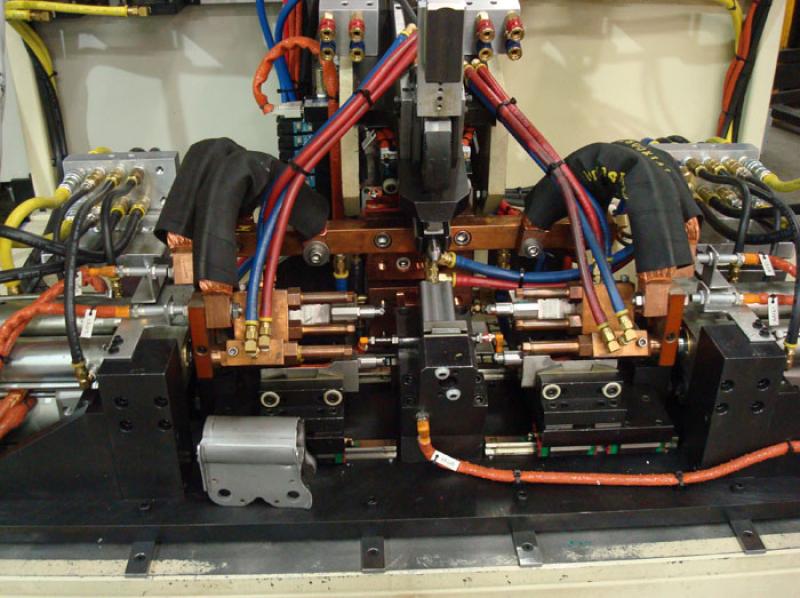

specialty weld fixtures for any application

Projection Welding Machine & Interchangeable Fixtures

Ready to reduce weld defects, shorten cycle times, and improve throughput?

Contact Quality Machine & Automation Inc. to discuss a tooling solution tailored to your welding process and production goals.

MANUAL BENCHTOP TOOLING TO INTERCHANGABLE ROBOT FIXTURES

mig, tig, resistance, nut/stud, hand fixtures, and more

Quality Machine & Automation Inc. delivers precision, reliability, and measurable ROI for manufacturers who demand superior weld tooling.

Why choose our weld tooling

Engineered accuracy: Our fixtures and tooling are machined to tight tolerances to ensure repeatable part placement, consistent weld gaps, and accurate heat distribution. This reduces rework and scrap caused by misalignment.

Robust durability: Built from high-grade materials and designed for heavy-duty production environments, our tooling maintains dimensional integrity over long production runs, minimizing downtime for repairs or replacement.

Customized solutions: We design tooling to your part geometries and process requirements — from single station fixtures to multi-part automation cells. Every solution is optimized for cycle time, ergonomic loading/unloading, and integration with your existing weld equipment.

Faster setup and changeover: Modular features and quick-clamp systems speed fixture setup and part changeovers, increasing uptime and supporting lean manufacturing practices.

Improved weld quality: By controlling part fit-up and repeatability, our tooling reduces weld defects, porosity, and distortion — improving first-pass yield and reducing welding rework costs.

Seamless automation integration: Our tooling is designed to interface with robotic weld cells and automation systems, including locator features, datum references, and tooling pockets for end-of-arm tooling, enabling reliable, repeatable automated welding.